Healthcare Electronics PCB Assembly

shenzen xinaoxun co.LTD founded in 2005, is a professional one-stop fast production service provider of PCBA, dedicated to providing high-quality EMS electronic manufacturing services for customers around the world.

product detail

- Place of Origin:

- Shenzhen, China

- Minimum Order Quantity:

- 1 piece

- Size:

- ≤ 510mm*510mm

- Material:

- General/High Tg FR4, High CTI, Aluminum Base, Copper Base, Rogers, Taconic, Arlon, Teflon, Isola, PI, Dupont, Panasonic

- Finished Copper Thickness:

- 1/3oz – 30oz

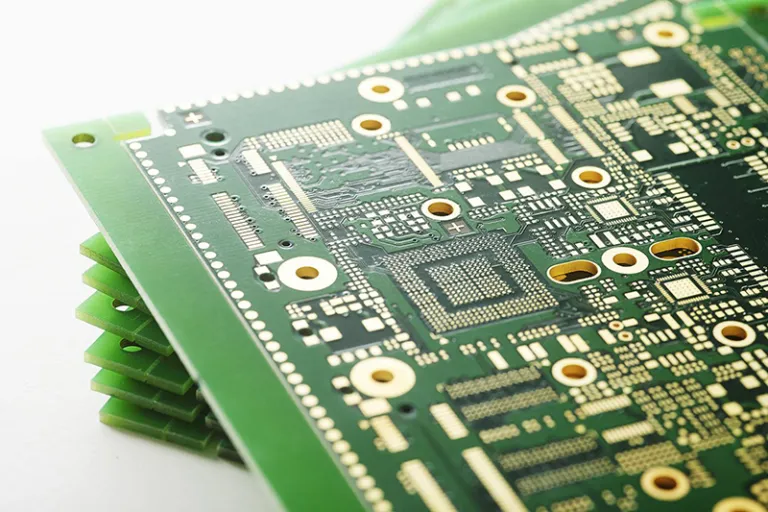

- PCB Layer:

- 1-30

- Color:

- Glossy/Matte: Green, Blue, White, Black, Red, Yellow, Purple, Pink

- Finishing:

- HASL Lead-free, ENIG, Immersion Tin, Immersion Silver, hard Gold plating (1-100U

- Certificate & Quality:

- ISO9001/IATF16949, IPC-A-610F, IPC Class II/Class III

product description

Shenzen Xinaoxun co.LTD, founded in 2015, is a professional one-stop fast production service provider of PCBA, dedicated to providing high-quality EMS electronic manufacturing services for customers around the world. We have extended our certification to the successful ISO9001:2015 and has a great advantage in the manufacture of BMS electronics PCBA in terms of high-tech, rich experience and cost down.

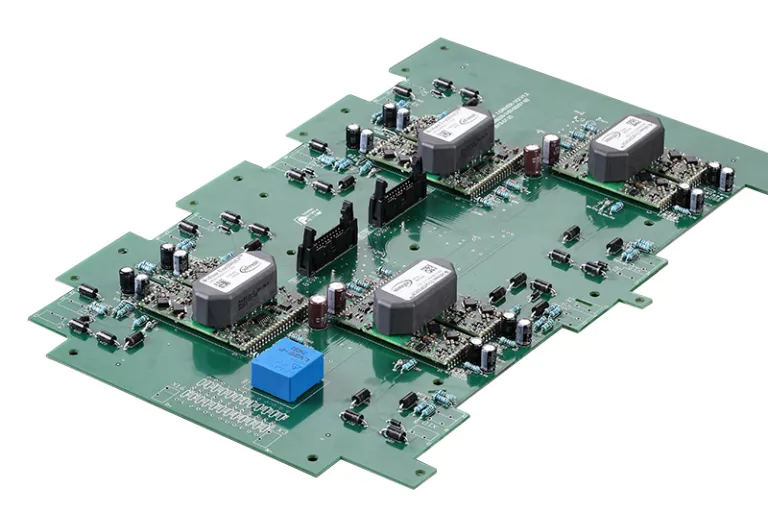

Xinaoxun has our own high-precision PCBA SMT assembly plant and THT/DIP assembly lines, as well as professional production testing equipment, experienced process R&D and production team, dynamic sales customer service team, and rigorous procurement team, so as to ensure that the PCBA products manufactured reach excellent quality standards and meet customer needs.

In terms of SMT process, we support low temperature lead-free, high temperature lead-free and red glue processes, which can be used to mount 20mm * 20mm to 510mm * 510mm PCBs, support the mounting of the minimum packaging component 0201, and support the mounting of BGA, PQFP, PLCC, SOP, SOJ and other integrated circuits.

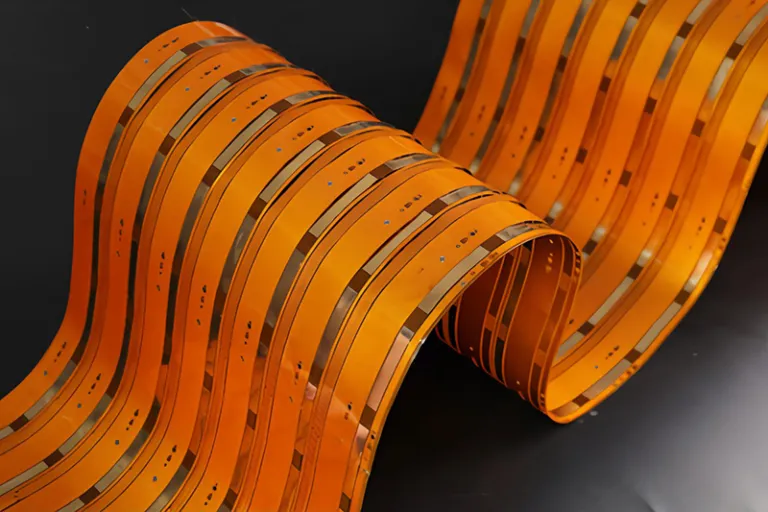

In terms of process control, we are very strict, including the mixing time of solder paste, the scrubbing time of steel mesh, the check of the first article, the check of feeding, and the IPQC routing inspection. We strictly follow the ISO9001: 2015 system standard and continue to improve, with the average pass rate above 99.9%. Our SMT workshop also supports the pick & placement process for FPC (flexible printed circuit board).